- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Place of Origin: JI NAN

- Brand Name: TORCH

- Model Number: D1

NHDD:

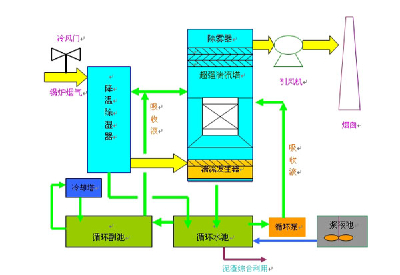

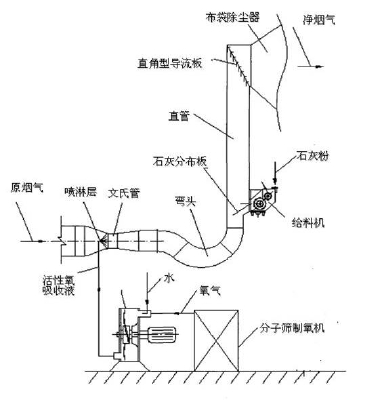

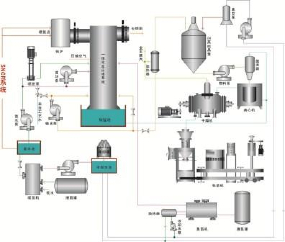

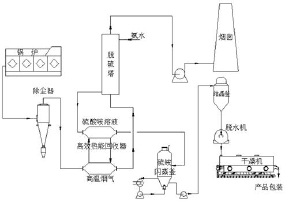

This process is a kind of efficient flue gas desulfurization and denitration and dust removal process, referred to as NHDD. The original boiler flue gas enters into the reactor and Venturi tube throat contraction area is arranged a plurality of nozzles composed of spraying layer, oxygen activation device to generate the absorption liquid through the nozzle spraying in Venturi tube throat contraction, dispersed into tiny droplets and cover the throat and the entire section of, droplet and throat in flue gas full contact, high strength and mass transfer occurs, the flue gas of no and SO2 is oxidative, soluble in droplet formation of nitric acid and sulfuric acid. In the reactor and area, with feeder into the lime for neutralization reaction, generate calcium nitrate and calcium sulfate; after the dust of the flue gas through the draught fan is discharged into the chimney. This process has the characteristics of high efficiency, low investment and low operating cost.

Wet desulfurization and denitrification:

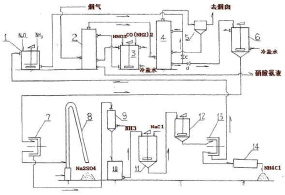

The process is not only desulfurization and denitrification in a process. And NaCI solutions were used to remove SO2 from flue gas by a certain concentration of NH4 and. The two products of NH4CI and Na2SO3 were generated. The NOX was removed by a certain concentration of nitric acid and urea solution, and the NH4NO3 product was formed. In brief, the mixed solution of dilute nitric acid and urea is used to remove the nitrate, and then the ammonia brine is used for desulfurization.

Four major advantages:

1, desulfurization and denitrification reaction rate is fast, high desulfurization and denitrification rate. The desulfurization rate is above 95%, and the denitrification rate is above 70%.

2 process desulfurization equipment is simple, investment in fixed assets than the limestone - gypsum wet desulfurization decreased by about 60%.

3, this process is not to spend any cost desulfurization, but also to create profit. This process to SO2 as a chemical raw material to use, each of 1 tons of SO2 theory can produce 1.67 tons of NH4CI and 1.97 tons of Na2SO3. A 2 x 200MW power plant, an annual output value of 400 million yuan, a profit of about 100 million yuan.

4, this process is to reduce the operation cost of fixed assets investment and denitrification than the SCR method to reduce by about 70%.

- Place of Origin: JI NAN

- Brand Name: TORCH

- Model Number: D1